Customer confidence regained! A contract manufacturing organization (CMO) masters the crisis through SCM excellence

New strength and customer confidence with excellent supply chain management (SCM) and transparent communication.

The performance of a contract manufacturer in the pharmaceutical industry, also known as a contract manufacturing organization (CMO), is measured by two key performance indicators: OTIF (On-Time In-Full) and the number of OOS (Out of Stock) caused by the CMO in the customer’s warehouse. Both key figures are crucial for patient care and are often linked to contractual penalties. Most recently, the CMO’s OTIF and OOS were outside the desired target range, which led to serious problems.

Initial situation: a drastic need for action

After a low point, the company management decided that urgent action was required. An interim manager from HANSE Interim was brought in to lead the supply chain management function and restore delivery performance and customer confidence.

The task: process-related and structural improvements

The objectives of our interim manager Kay Bindel were clearly defined:

- Improving the fulfillment of production planning

- Regaining the trust of customers

These tasks required procedural and structural changes, as management weaknesses and a lack of expertise were identified as the main causes of the problems.

Process and structural improvements were also to be achieved in consultation with the most important customers, large pharmaceutical companies.

A Project Director Supply Chain Management was therefore appointed to the specialist department until the department’s performance was significantly improved.

The interim manager had the special task of improving the delivery performance of the site at short notice and with all his might in order to regain lost customer confidence and also to implement optimizations in the handling of day-to-day business.

To make matters worse, other members of the management team had left the company or had to leave at short notice, as did the managing director.

The solution: A strategic approach to problem solving

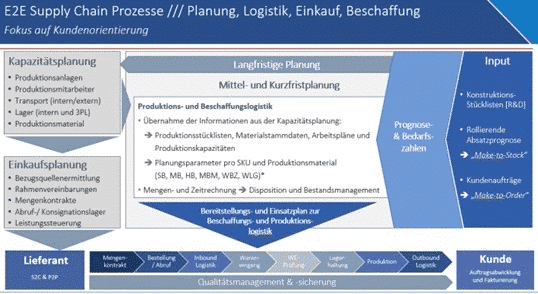

In the first two weeks, the interim manager gained a comprehensive overview of the end-to-end supply chain processes and the internal and external customer-supplier relationships.

A detailed DMAIC analysis (6 σ) helped to identify weaknesses and develop appropriate measures.

E2E Supply Chain Processes

Measures to improve communication

A two-day workshop was organized with a key customer to restore trust and improve communication. Joint measures were developed to improve communication, e.g. with escalation rules. Early information about emerging difficulties and possible remedial actions ensured that customers were satisfied.

After a few weeks, the improved communication had become established and this measure alone made the customer very satisfied.

“Even if things can’t always run optimally, a customer must be informed at an early stage about any difficulties that arise and possible remedial measures”

Organizational adjustments and teamwork

Organizational conclusions were drawn from the as-is analysis of the E2E processes.

The far more complex task for the interim manager was to draw the right organizational conclusions from the results of the as-is analysis of the E2E processes and, in the next step, to define the necessary measures that could then ultimately be implemented.

The interim manager was assisted in this by a close exchange with the department heads of the SCM division, the management, the works council and the HR department.

Workshops to improve processes

Workshops were held in smaller teams to clearly define areas of activity and eliminate weak points.

Once the main tasks had been developed in the E2E process, workshops were held in smaller teams. The respective activity packages were developed for all main tasks. This involved checking which interfaces might have weak points that could be eliminated by improving the allocation of activities.

Optimization of procurement

One major success was the bundling of activities in the new Requirements Planning & Procurement department, which optimized operational procurement.

One of the results was that Production Planning had previously also carried out the operational procurement of production materials, but lacked the expertise and processing capacity to do so.

Delimitable activities were therefore bundled in the new Requirements Planning & Procurement department and assigned to the newly created Materials Management department, which also includes all warehouse logistics for production materials. To this end, the previous purchasers have taken over all operational procurement tasks.

This met with some resistance from the purchasing staff. Thanks to his many years of experience, the Interim Manager was able to explain this away very well, resulting in a new level of satisfaction and a new team spirit among the employees.

KPI dashboard and new measurement methods

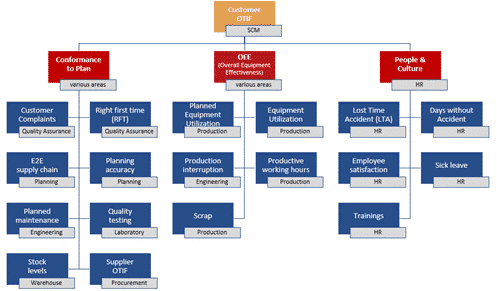

Another extremely important measure taken by the interim manager was to convince the entire management team, consisting of the nine divisional managers, that the success of a CMO is measured by OTIF and not, as previously, by the packs produced.

E2E KPI-Dashbord

The sometimes significant resistance was discussed and resolved in a joint management workshop.

The interim manager developed a KPI dashboard for this purpose, with the customer OTIF as the top KPI.

This KPI is cascaded to all functional areas in order to make success measurable and continuously improve it.

The implementation of the KPI dashboard developed by the interim manager will still take time in the company. The resources required to set up a tailor-made SCM controlling system are being developed

“Only what can be measured can be improved!”

The result: a successful turnaround

The measures taken by the interim manager led to significant improvements:

- Confidence in its own abilities: The organization has regained confidence in its capabilities.

- Improved OTIF: The OTIF has been significantly improved so that OOS are no longer the fault of the CMO.

- Transparent communication: Difficulties are communicated transparently, which strengthens customer confidence.

- Structural changes: Two retiring department heads did not need to be replaced.

- Functioning department: A functioning department with team spirit, motivation and goal orientation was handed over.

Conclusion

The interim manager’s authentic manner and his mix of methods, based on many years of experience, were the key factors for success. The CMO’s turnaround shows how important targeted measures and a structured approach to supply chain management are in order to regain customer trust and sustainably improve delivery performance.

Kay Bindel, the interim manager nominated by HANSE Interim, was voted AIMP’s Interim Manager of the Year 2024.

Interim Manager Kay Bindel

What measures do you consider crucial for regaining customer trust in challenging times?

Feel free to share your experiences and opinions in the comments!

With kind regards

Your HANSE Interim Management

Andreas Lau