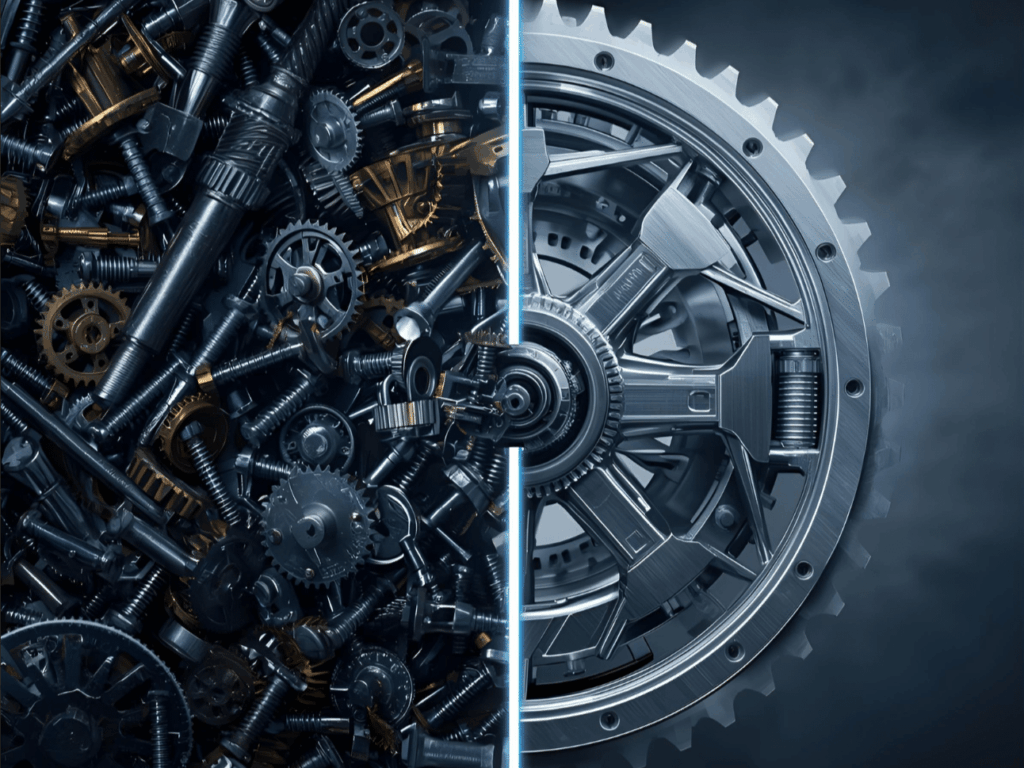

From Juggling to Precision

How an Interim Manager brought an automotive supplier back on track

Starting Point: A Traditional Company in Distress

For many years, the family-owned company was regarded as a highly specialized partner to the automotive industry. With precision metal parts at nanometer level, it had built a strong reputation. But the decline in demand for combustion engines led to drastic revenue losses.

The consequences were clear: the financial situation deteriorated, customers complained about delivery failures, and new projects hardly got off the ground. At the same time, management changes were looming. Both the external CEO and the CFO planned to leave. The organization was on the brink of losing control.

The Assignment: Restructuring Without Banks

In this critical phase, HANSE Interim placed the experienced restructuring expert Guido Beyß as Interim Manager. The mission was clear: restructuring under the company’s own steam, without involving the banks.

The goal was to contain losses at the main plant, identify the key problem areas, implement immediate measures and initiate the turnaround. The target: achieve break-even within 18 months.

Right from the first deep dive, however, one major obstacle became apparent. Data quality in the SAP system was so rudimentary that reliable analyses were impossible. Experience, operational proximity and pragmatic action were required.

First Steps: Creating Breathing Space for the Organization

The prerequisite for any change was to move the organization out of constant reaction mode and restore its ability to act.

For the critical production ramp-ups, a dedicated team was established that worked exclusively for the most important customer. All necessary technical and operational resources were bundled here. The company sent a clear signal of focus and commitment.

At the same time, it was vital to rebuild customer trust. Instead of hectic war-room calls, contradictory ad hoc measures and expensive special shipments, what was needed was stability and reliability.

Root Cause Analysis: Production Planning in Focus

It soon became clear that the root cause of many problems lay in production planning. The old push system was based on faulty machine data and led to unrealistic delivery promises.

The solution consisted of several steps:

- Transition to a pull-based planning system

- Adjustment of SAP work schedules

- Consideration of idle times and realistic changeover processes

The results were immediately visible. Deliveries were once again reliable, war-room calls disappeared and costly special freight was eliminated.

Machine availability increased noticeably.

At times, machines even stood idle due to missing upstream material.

These pauses were used for preventive maintenance, further improving machine performance.

The Human Factor: Motivation Instead of Temporary Labor

The problems did not lie in systems alone. On the shop floor, dissatisfaction was high and absenteeism rampant. In the past, the company had tried to counteract this with temporary workers, but given the high precision requirements this was hardly feasible.

Guido Beyß focused instead on:

- Cross-training employees

- More effective staff deployment

- Reducing reliance on temporary labor

- Conducting return-to-work interviews with half of the workforce

- Consistent separation in individual cases

These measures not only increased the availability of qualified staff, but also reduced quality costs, which had previously been driven up by constantly changing temporary workers.

Hidden Threat Identified: New Projects Could Have Led to Millions in Losses

As the mandate progressed, another risk became apparent. The costing of new projects was not aligned with real production data. If left undiscovered, the company would have incurred major losses with every new order. The danger amounted to tens of millions.

Through systematic recalculation, this risk was eliminated. New hourly rates were developed, product costs were estimated more realistically, and a solid basis for price negotiations with customers was created.

Results: Break-Even Achieved Earlier Than Planned

The impact of the measures was clear:

- Break-even was reached ahead of schedule, within the current financial year and well before the original 18-month target

- Capital tied up in inventories was reduced through consistent stock reduction

- Delivery performance stabilized and customer trust was regained

- Machine and workforce productivity increased significantly

- A multimillion loss was prevented through corrected project costings

As a result, the company was placed back on solid ground. The new CEO now has the opportunity to sustainably develop the family business further.

Conclusion: Back to Precision

This project story demonstrates the impact of Interim Management when experience, operational clarity and consistent execution come together.

Back to precision!

HANSE Interim Manager Guido Beyß

His mandate not only stabilized a company but also showed the importance of moving beyond constant reaction and regaining the ability to act.

Or, as Winston Churchill put it:

“It is not enough that we do our best; sometimes we must do what is required.”

What experiences have you had with Interim Management in transformation or restructuring processes?

We look forward to hearing your thoughts and questions in the comments.

Best regards

Your HANSE Interim Management

Andreas Lau